随着现代材料技术的不断进步, 钢化玻璃 不再只是简单的透明介质;它已成为集安全性、耐用性和美观性于一体的关键材料。无论是在建筑幕墙、家居装饰,还是智能电子设备中,钢化玻璃都展现了其独特的价值和不可替代性。随着工业需求的不断增长,该材料将成为未来产业升级和设计创新的关键驱动力。

钢化玻璃的基本原理及加工特点

钢化玻璃是一种特殊类型的玻璃,采用物理或化学方法进行二次加工,使其表面产生压应力,内部产生拉应力。这种内部应力分布不仅显着提高了其抗冲击性,而且在破碎时会产生钝角颗粒,从而降低受伤风险。传统玻璃的脆弱性在于其应力分布不均匀。而钢化玻璃通过加热至软化点附近然后快速冷却,锁定了表层的分子结构,从而显着提高了机械性能。

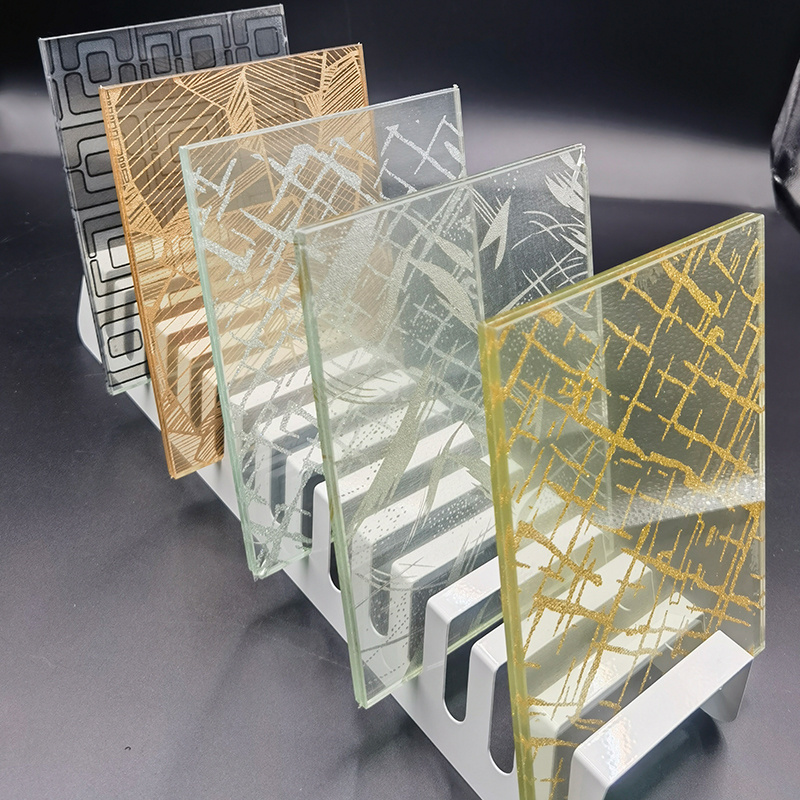

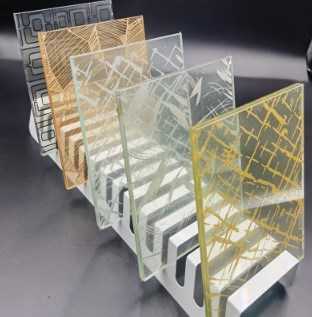

钢化玻璃的光学性能也高度稳定。高透光率确保建筑物或产品在整个使用过程中保持清晰明亮。此外,该加工允许多种设计可能性,例如弯曲、涂层和丝网印刷,为设计师和制造商提供了很大的自由度。

钢化玻璃在建筑中的广泛应用

在现代建筑中,钢化玻璃已成为不可缺少的核心材料。高层建筑的幕墙必须承受风压、温度波动和外部冲击。钢化玻璃具有高强度和耐候性,是确保结构稳定性和美观的关键组成部分。无论是透明的落地窗,还是大型的圆顶和天窗,这种玻璃在保证安全的同时,又展现出开放、透明的美感。

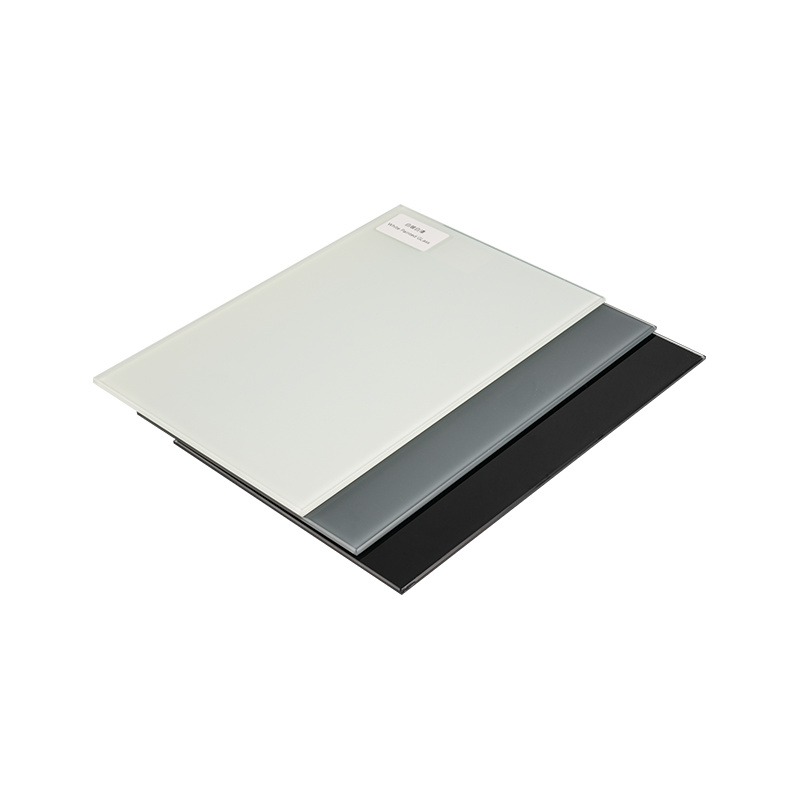

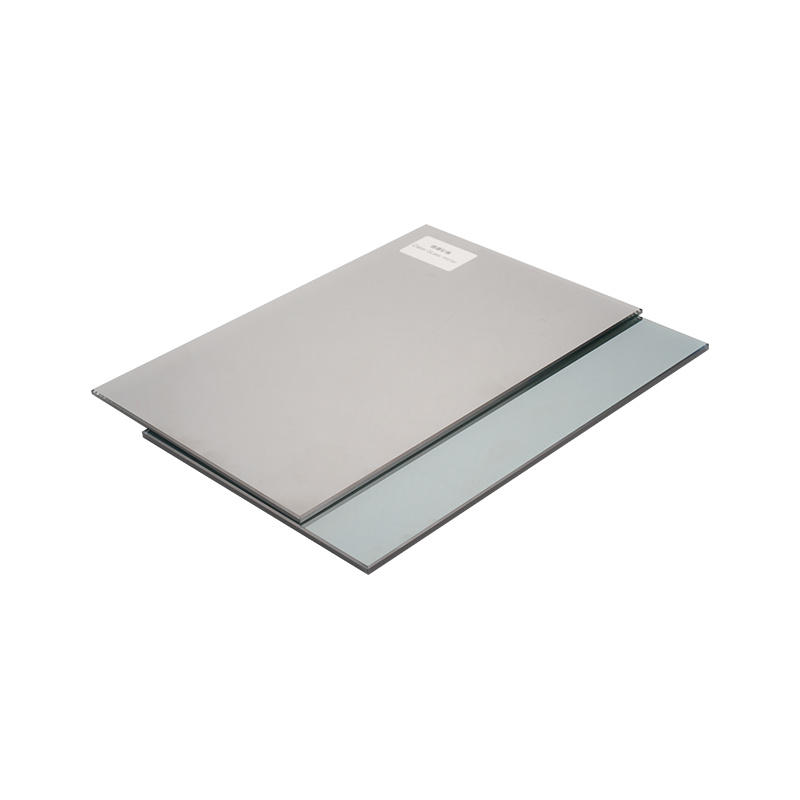

随着绿色建筑理念的兴起,钢化玻璃的节能潜力日益被挖掘。钢化玻璃与中空玻璃和Low-E镀膜玻璃结合,可以有效增强隔热、隔音效果,帮助建筑降低能耗,创造更舒适的室内环境。在建筑行业,它不仅是一种安全材料,也是绿色可持续发展的重要组成部分。

钢化玻璃在消费电子产品中的重要作用

智能手机、平板电脑和可穿戴设备等消费电子产品的广泛采用导致钢化玻璃在另一个主要领域的显着增长。屏幕作为人机交互的核心部件,必须同时满足高清显示、触摸灵敏度、抗冲击等要求。钢化玻璃由于其高硬度和耐刮擦性,已成为电子设备屏幕保护的首选。通过专门的镀膜工艺,还可以实现防指纹、防眩光、增强触感,显着提升用户体验。

随着消费电子产品的快速发展,钢化玻璃加工技术也在不断发展。例如,超薄钢化玻璃的出现使设备能够在不牺牲耐用性的情况下保持纤薄的设计,而曲面钢化玻璃则为可折叠屏幕和可穿戴设备提供了新的设计可能性。这些进步表明钢化玻璃不仅仅是一种被动防护材料;它是产品创新的重要组成部分。

扩大钢化玻璃在家居和交通领域的应用

除了建筑和电子产品之外,钢化玻璃在家居和交通领域的价值也很重要。现代家居追求简洁、透明。采用钢化玻璃制成的门、窗、隔断、家具台面,不仅满足美观要求,而且增强了安全性。与传统玻璃相比,钢化玻璃在日常使用中更加耐用、抗冲击,有效降低破碎风险。

在交通领域,钢化玻璃因其高安全性和稳定性而被广泛应用,从汽车的前后挡风玻璃到地铁和飞机的车窗。尤其是在高速环境下,玻璃的稳定性直接关系到乘客的安全。钢化玻璃通过严格的工艺控制,确保其在极端条件下的可靠性能。

从最初的安全需求到如今的多样化应用,钢化玻璃已经从基础建筑材料跨越到高科技材料。它不仅仅是一块玻璃;它是一种集安全性、功能性、美观性于一体的综合材料。随着全球产业不断升级,钢化玻璃的应用边界将不断扩大,其在未来材料领域的战略地位将日益凸显。

English

English